| Tips you should know to buy laser marking machine in China |

| Release time:2020-06-08 16:25:29| Browse times : |

Choosing a laser marking machine is the same as what we usually buy. The best is not necessarily the most expensive, and the most expensive is not necessarily the most suitable. Let HJZ Laser tell you some tips for choosing laser marking machine:

1. Laser sourceFirst, confirm the material of your product, because different materials absorb lasers to different degrees, and the degree of light absorption is determined by the wavelength of the laser. Different laser wavelengths are named different laser sources, so for different materials, you must choose Different laser sources.

Fiber laser marking machine, wavelength 1064nm, main application areas: hardware, plastic, label paper, etc.;

Carbon dioxide laser marking machine (co2 laser marking machine), wavelength 10.6μm, main application areas: bamboo, cloth, ceramics, acrylic, leather, etc.;

Ultraviolet laser marking machine (UV laser marking machine), wavelength 355nm, main application areas: silicone, UV plastic, paper, glass and other heat-sensitive materials;

Green laser marking machine with a wavelength of 532nm, the main application areas: film, fruit, eggs, cartons, strengthened glass and other heat-sensitive materials.

Is it possible to use only one laser source to engrave a material?

Of course not, some materials are suitable for multiple laser sources, but the degree of laser absorption in different wavelength bands is different, and the effect presented is good or bad, depending on the user's acceptance. For example, glass engraving:

Carbon dioxide laser marking machine-glass is rough and easy to produce glass slag;

UV laser marking machine-cold light source, glass marking is very fine and uniform;

Green laser marking machine-glass engraving, internal plane engraving.

HJZ LASER reminds you: to determine what laser is suitable for your product, you need to test specific samples, see the final effect. The point is: sample proofing! Sample Proofing!sample Proofing!

2, the marking machine power

Laser power is sometimes the key to determining speed and effect. Different laser sources have a most stable power range:

Fiber laser marking machine with 20W/30W power is the most stable; 30W power of co2 laser marking machine is the most stable; The ultraviolet laser marking machine 3W/5W power is the most stable; The green laser marking machine 3W/5W power is the most stable. Choosing the right power depends on the material of the product first, like UV engraving paper, film, plastic, low-power 1.2W marking can also be used, if engraving glass requires UV 3W, even 5W power can be engraved.

The second point of view is efficiency. For example, hardware is generally marked with 20W optical fiber. If efficiency and speed are pursued, using 30W optical fiber with high power is of course more efficient. Of course, to determine whether the power purchased by yourself is the most suitable, it is recommended to test with specific samples, depending on the effect and the marking time. 3, the hardware configuration of the marking machine

The main hardware structure of the laser marking machine: 1). LaserThe laser source, the core of the laser marking equipment, is installed in the equipment casing. The imported fiber laser has good output mode and long life. In recent years, the technology of the domestic laser industry has gradually matured, and the life and performance of the laser can also be comparable to imported lasers. However, for users with very high accuracy requirements, it is recommended to explain to the manufacturer in advance and make requirements. HJZ LASER provides domestic and imported lasers; domestically selected fiber lasers of well-known brands Raycus/JPT and imported US IPG. 2). Laser scanning galvanometerThe optical scanning galvanometer is also the core component of the laser marking machine, which is mainly used for fast and accurate positioning of the beam. The performance of the galvanometer determines the accuracy of the marking machine.

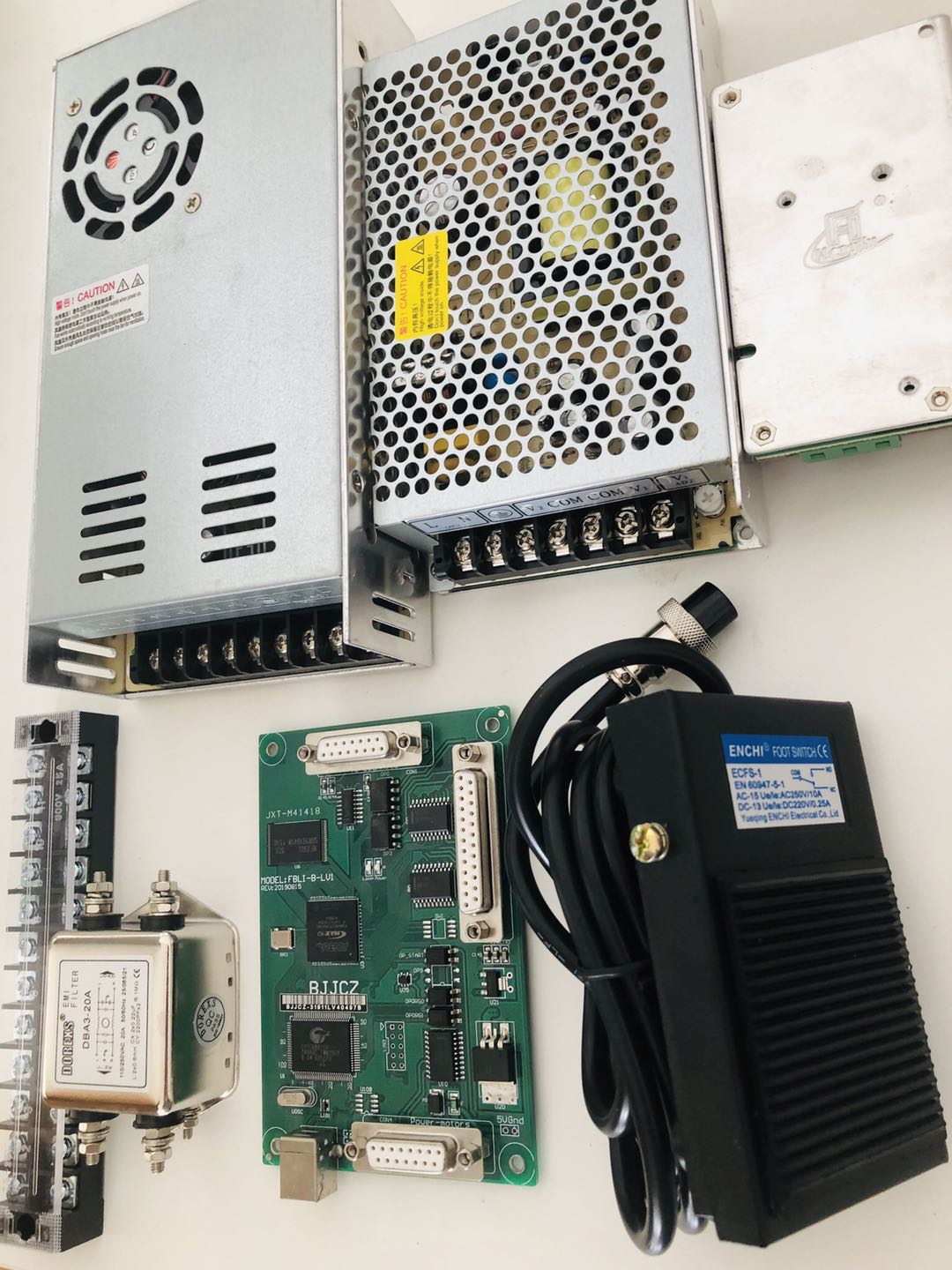

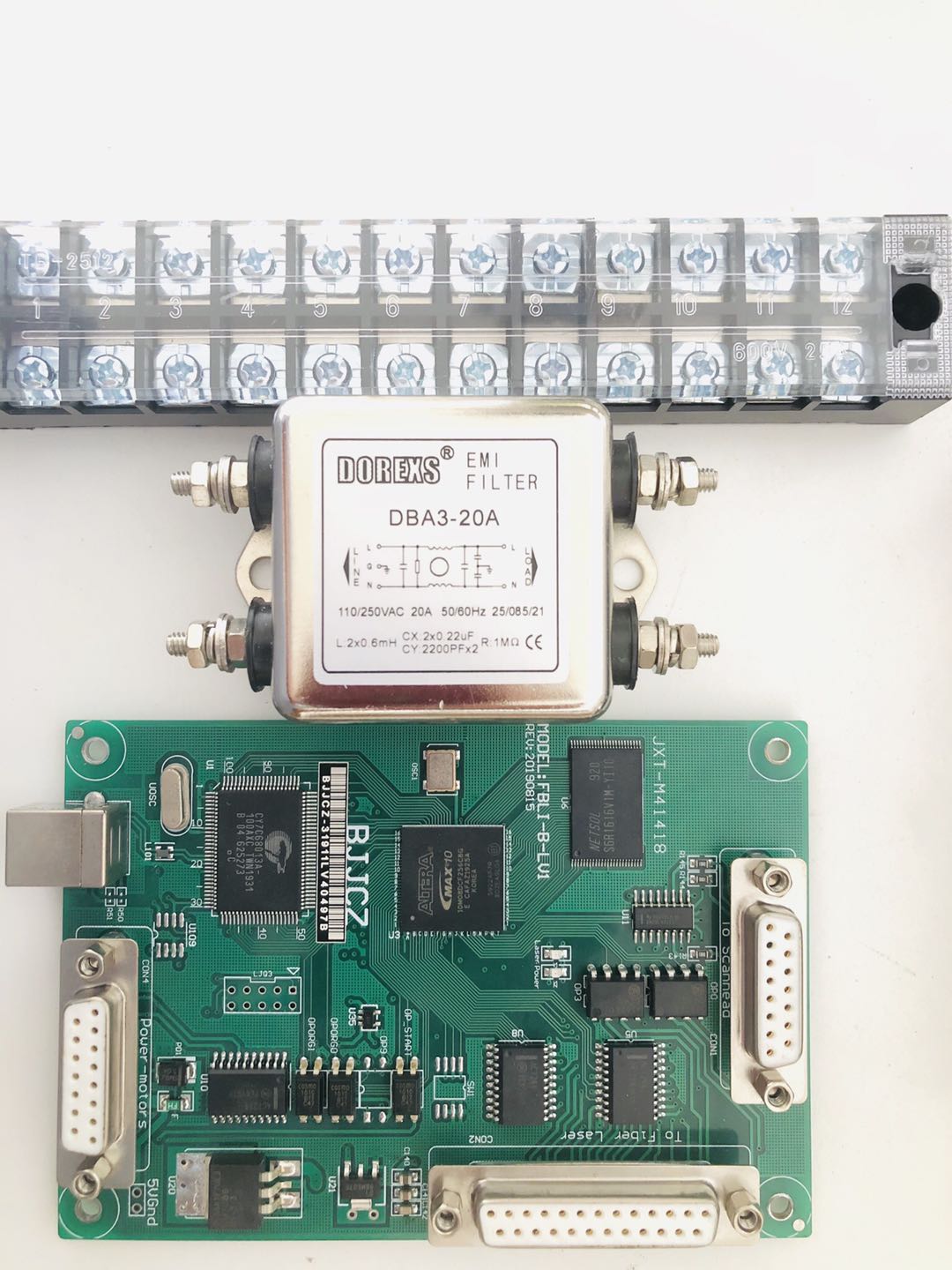

HJZ LASER selects high-speed scanning laser galvanometer system. The laser wavelength is different, and the laser scanning galvanometer also needs to match the four scanning galvanometers of fiber galvanometer, co2 galvanometer, ultraviolet (355 galvanometer) and green light (532 galvanometer). 3). Focusing systemThe focusing system focuses the parallel laser beam at one point, mainly using f-θ lens (also called field lens). Different field lenses have different focal lengths and different marking effects and ranges. The standard field lens of fiber laser marking machine Generally: f=160mm, effective marking range Φ=110*110mm, users can choose the field lens model according to their products and the marking range needed: f=100mm, effective marking range Φ=75*75mm f=160mm, effective marking range Φ=110*110mm f=210mm, effective marking range Φ=150*150mm f=254mm, effective marking range Φ=175*175mm f=300mm, effective marking range Φ=220*220mm f=420mm, effective marking range Φ=300*300mm Due to the different wavelengths of the laser source, the focusing system also needs to be divided into fiber field lens, co2 field lens, ultraviolet (355 field lens), green light (532 field lens). 4). Laser power supplyThe input voltage of the laser power supply is AC220V alternating current, and the Adidas minicomputer is equipped with a switching power supply for easy portability and emergency stop. 5). Computer control systemThe combination of laser processing system and computer numerical control technology constitutes highly efficient automatic processing equipment, which can print various texts, patterns, symbols, one-dimensional codes, two-dimensional codes, etc. It is easy to design marking patterns with software, change the marking content, and adapt to modern production Requirements for high efficiency and fast pace.

There are many kinds of software used in the laser marking machine, some are conventional, some are developed by ourselves, or the conventional software is developed for the second time, mainly depends on what control card is used by the equipment manufacturer and decides which software to use.

The first one:EZCAD. This software is used the most. At present, laser equipment manufacturers of minicomputers generally use this software. There are many patterns designed by this software. The main problem is different for upgrade function development

The second kind: Taiwan Qingyu software, this is quite satisfactory, can meet the general needs, secondary development is generally difficult, domestic users are relatively less than EZCAD, but foreign countries such as Thailand and India generally use this software More.

The third type: LS8001 software and marking machine, this model has few users, but its advantage is that the secondary development is not difficult, you can easily complete and add unused functions.

At present, some super brand manufacturer in the laser industry, has a large number of users of their own developed by itself, but the post-sale software maintenance cost is high. At present, the models used by HJZ LASER are basically equipped with EZCAD software. The marking software is easy to operate and powerful, compatible with the output files of CoreIDRAW, AutoCAD, Photoshop and other software, and also supports PLT, DXF, JPG, BMP and other files. HJZ LASER marking software international edition secondary development function:1) Receive and obtain 11 data transmitted from two serial ports; 2) Update marking content in real time, including real-time time to seconds; 3) The starting shift group number can be set manually; 4) The group number is accumulated every time the marking is made; 5) After the marking is completed, the 11 pieces of data received will be saved in the EXCEL form corresponding to the marking code. 4, the origin of the marking machine

The four places of laser marking machines are relatively well-known: Wuhan in Hubei, Shenzhen in Guangdong, Liaocheng in Shandong, and Zhejiang.

The area around Shandong Liaocheng is mainly used for recycling and refurbishment of laser marking machines, and the price of fiber laser marking equipment is as low as more than 10,000 or even 8,000 rmb. The e-commerce model is followed in Zhejiang, using low-cost accessories, small profits but quick turnover, and the price is relatively low. The laser marking machines in Guangdong are mainly concentrated in Shenzhen and Dongguan generation. They mainly do configuration processing and pay attention to appearance design. They are called "design capital" and the price is relatively high. Wuhan, Hubei, is known as "the birthplace of lasers" in China. Many high-tech developments have been well developed here. The laser manufacturers in Wuhan have relatively high requirements for the quality of equipment parts and production, and the use of laser technology in automation is more. Equipment prices are also higher than those in Shandong and Zhejiang. 5. Marking machine priceThe price of fiber laser marking machine (20W-120W) ranges from 20,000 to 200,000rmb; Carbon dioxide laser marking machine (10W-100W) prices range from 30,000 to 180,000rmb; The price of ultraviolet laser marking machine (1.2W-10W) ranges from 60,000 to 260,000rmb; The price of green laser marking machine (3W/5W) ranges from 60,000 to 80,000rmb. These prices will change according to the configuration selected by the user. HJZ LASER provides non-standard automation solutions. The prices are analyzed according to the needs of users and the specific problems of the configuration. 6, the life and stability of the marking machine

The laser will be gradually worn out during long-term use. Many people mistakenly think that the greater the laser power, the longer it is consumed, and the longer the life of the laser. In fact, the greater the laser power, the more heat is generated during operation. If the heat can not be dissipated in time, the long-term high temperature of the equipment will shorten the life and burn out easily. Therefore, the equipment with optical fiber 50W and ultraviolet 3W and above needs to be equipped with a large cooling system for water cooling. Therefore, the higher the wattage, the longer the life is not guaranteed. If the cooling system is not done well, it will be more likely to burn out, but also increase the cost of heat dissipation. 7. Product appearance and model of marking machine

At present, the appearance of the laser marking machine is mixed with dragons and dragons, and the styles are variable. There are small portable laser marking machines, desktop laser marking machines with cabinet operation tables and computers, and flying laser marking machines for automatic assembly lines. . 8. Brand of marking machine manufacturers

When choosing the brand of laser marking machine, it is recommended to look at the manufacturer/distributor first, the manufacturer's brand/no brand, and the manufacturer's strength. To ensure that the after-sales service of the equipment after the purchase can keep up. Example: We visited a customer of a listed company, and the customer told us a period of experience in purchasing laser equipment. At that time, the customer did not inspect the factory and purchased the required imported laser, and paid a 30% deposit. The trial payment was made after three months, but The device failed within two months, and the manufacturer could not be contacted when looking back. The customer asked for someone to disassemble the device to find out that the laser was not imported. 9, after-sales service of marking machineThe operation of the laser marking machine requires the guidance and training of engineers. Especially the application skills, parameters and daily maintenance of equipment marking software. The warranty period of electronic products is one year, and some manufacturers promote the warranty period of three or five years to attract customers. In fact, the accessories of the laser marking machine are well selected. Because the equipment has no consumables and no consumable parts, the equipment has a high maintenance-free rate. The lifetime of today's laser equipment reaches 60,000 to 100,000 hours, and there is no problem in three to five years. HJZ LASER has after-sales engineers responsible for connecting with customers, so you can worry-free after-sales. 10. About customization and others

When using laser equipment, the requirements for accuracy, engraving effect, speed, coordination with automation, custom jigs, etc., should be proposed to the manufacturer in advance, and confirmed during the sample testing and solution process, so as not to purchase markings that do not meet the user's requirements. Machine, affecting the user experience. |

| Last chapter:How thick can hand-held laser welding machine weld Next chapter: |